Prestressed Power Spring

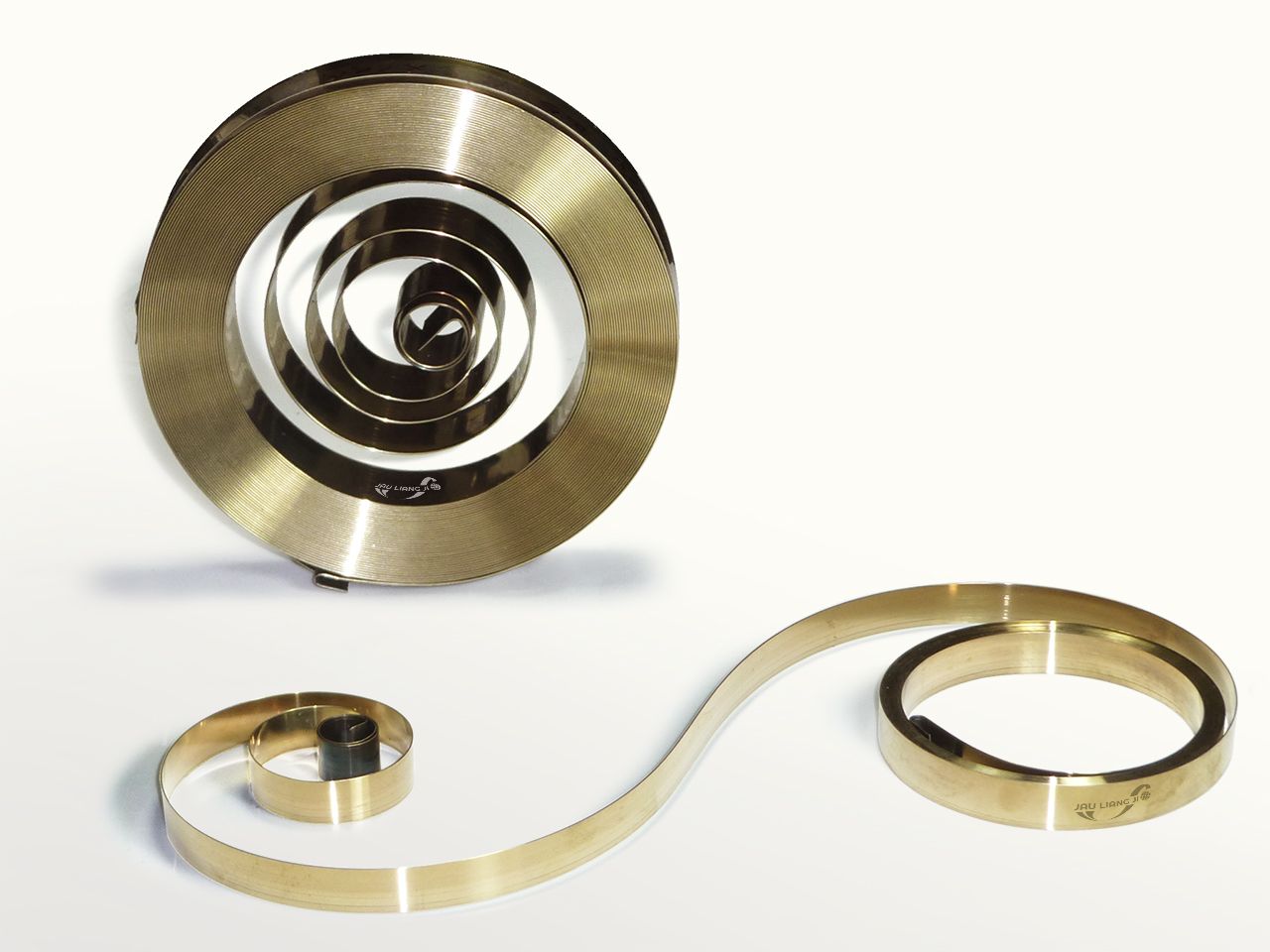

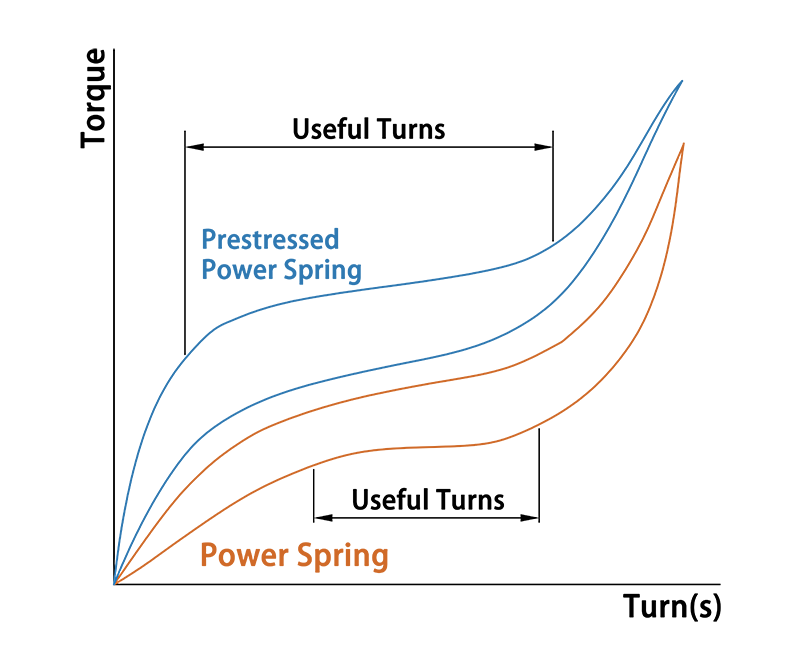

A prestressed power spring is wound around the shaft in the opposite direction and spreads out into a closed housing, which is S-shaped in the free state. It can produce higher stresses and, on the conditions of same torque and deflection, the prestressed version can create 25% to 55% more torque than a typical power spring and has a flatter torque gradient in comparison.

A prestressed power spring can achieve the same torsional moment as a normal power spring using a thinner material in the same space and can produce a higher number of coils.

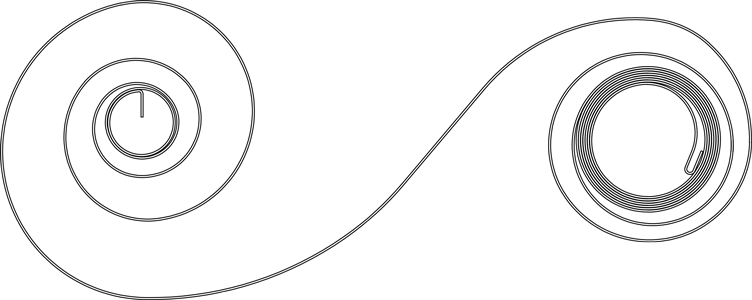

In general, it is difficult to distinguish between a normal power spring and a prestressed power spring when they are placed in the enclosure, and they may even look the same, but when not in the enclosure and are free, the normal one has a helical shape while the prestressed one has an S-shape.

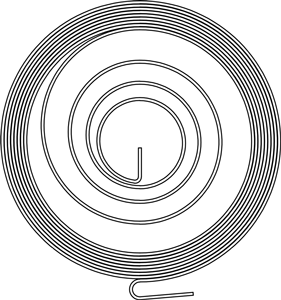

Power springs in the free state

Prestressed power springs in the free state

The advantages of power springs in general are lower stresses, longer cycle life and easier manufacture compared to pre-stressed power springs.

A prestressed power spring can produce 25% more torque than a normal power spring and has a flatter torque gradient in comparison. Both designs have their own strengths, so it is advised to choose the most suitable type of spring for each application.

Thanks to their capability to store large amounts of rotational energy, power springs and prestressed power springs are widely used in automobiles, healthcare, industrial applications, commerce, aerospace, as well as in extension mechanisms for electrical wires and safety belts

To satisfy the requirements of these different applications, Jau Liang Ji Co. offers customized power springs for applications and solutions based on years of expertise and experience, with sizes to suit your needs. Our experienced engineers can assist you with your spring design, please contact us for more information.

Product Applications

Various auto rewinding devices, Industrial tools, Medical appliances, Automotive Industry, Seat belt springs

Service life

Many factors affect cycle life including spring forming methods, edge condition and lubrication.

Different materials and storage methods may also affect the service life of the finished spring, such as frequent exposure to extreme temperatures or to corrosive gases.

Material

SUS stainless steel is generally recommended, but other special materials are available on request.

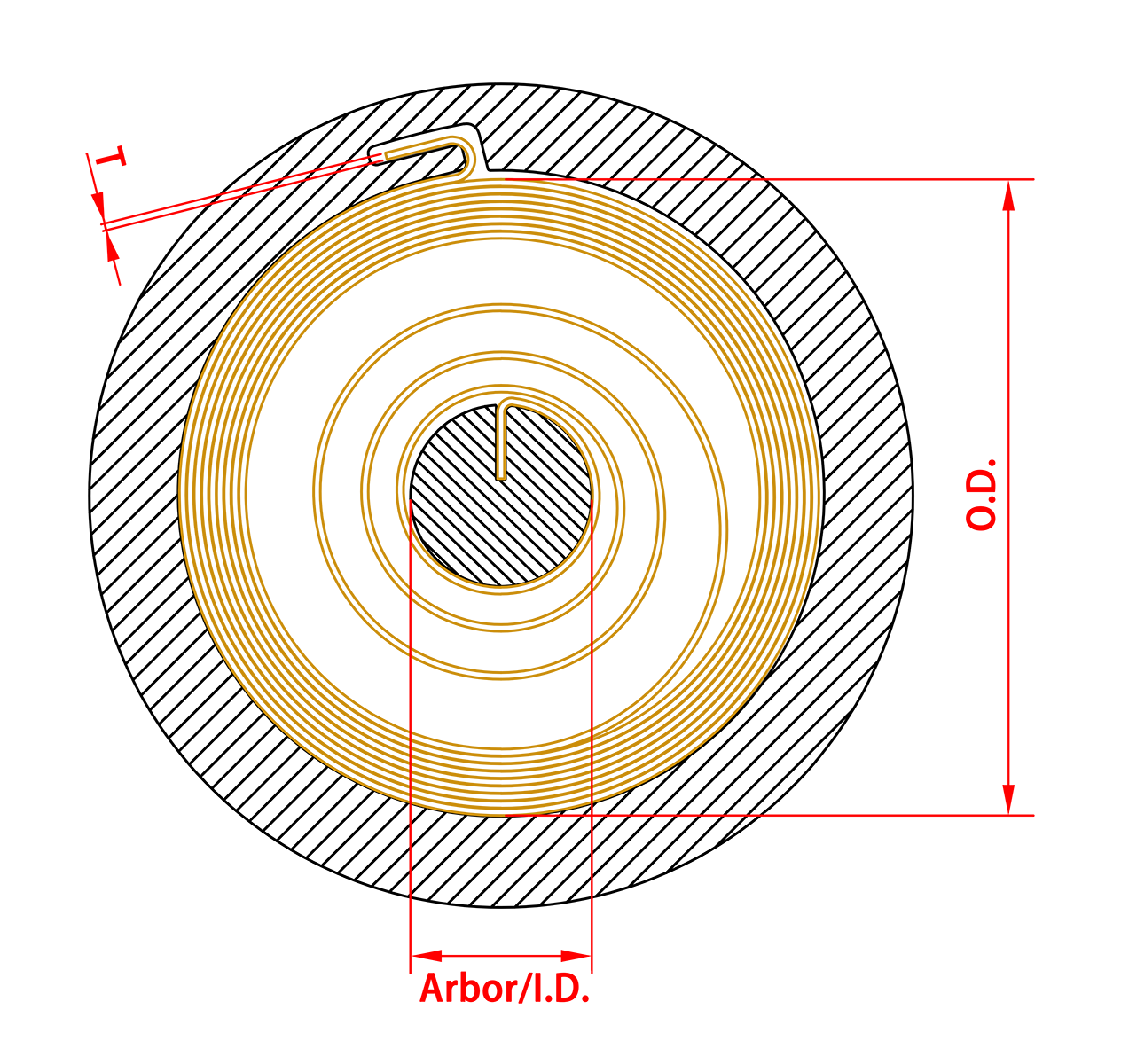

Dimensional Design

Since the performance of power springs or prestressed power springs depends on the manufacturing technology,

it is usually necessary to specify the shaft, housing, total number of coils, head/tail pattern and functional characteristics and to specify the tolerances.

The thickness, width and length of the material can also be provided as reference dimensions;

usually the torque is provided as a minimum or maximum value at a fixed number of revolutions, with a general torque tolerance of 15%.

- Thickness of spring(T)

- Width of spring(W)

- Arbor /Inner diameter(I.D.)

- Housing /Outside diameter(O.D.)

- Number of Spring Coils

- Torque

- General tolerances: +/- 10%