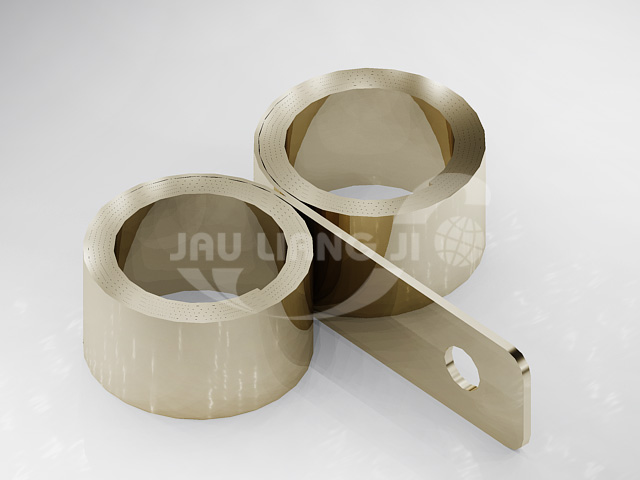

Constant Force Spring

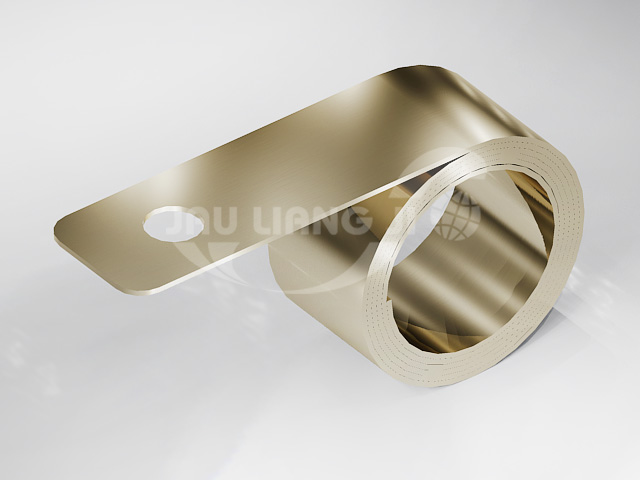

It consists of a flat strip of steel-belt material cut to a certain length and tightly rolled to store energy and, after stretching the constant force spring, it is automatically wound back to produce elasticity.

Constant force springs do not require much space to provide a high force output; their characteristic is that they maintain almost the same force over the effective stroke, which can be varied depending on the customer's requirements, without any limitations.

The features of constant force springs make them ideal for applications where linear movements such as tension, retraction, balancing, etc. are required.

Product Applications

LCD displays, Fan height adjustment, Windows, Curtains, Cable retractors, Nail guns, Medical devices

Service life

The thickness, width and inner diameter of the plate not only determine the force of the spring, but also its life cycle depending on the size of the spring, which is stretched out and then retracted for a cycle period.

Different materials and storage methods may also affect the service life of the finished spring, such as frequent exposure to extreme temperatures or to corrosive gases.

Material

SUS stainless steel is generally recommended, but other special materials are available on request.

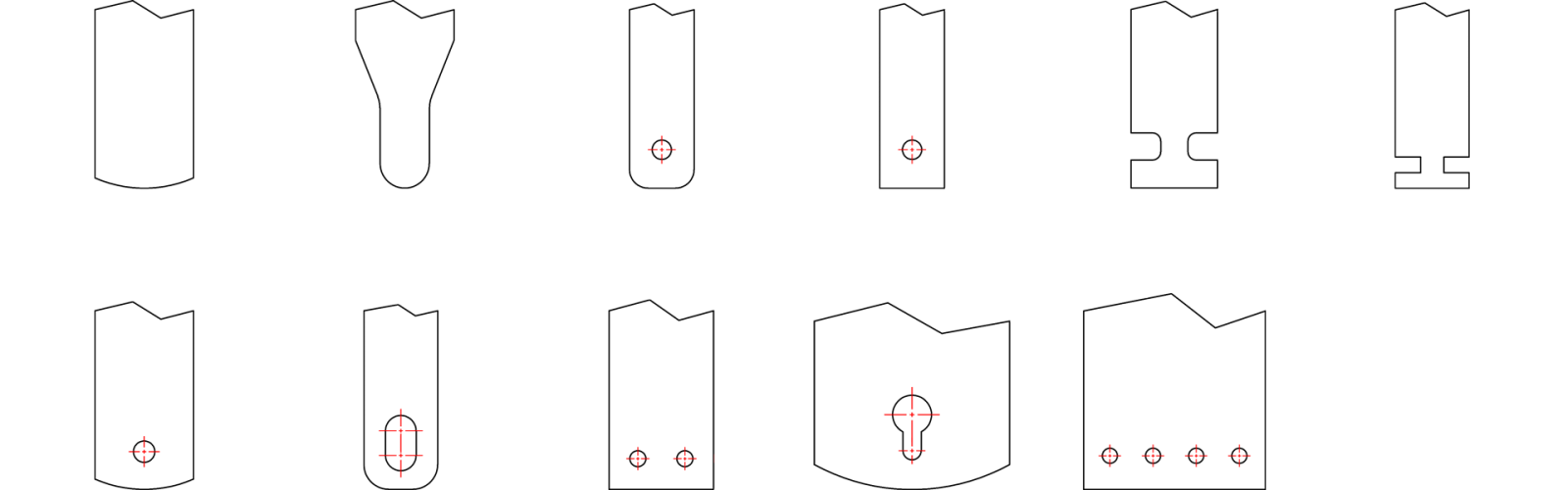

Tail end design

Below you will find a selection of common spring end designs. If you require a custom design, we will be happy to tailor it for you. For more information, please contact us.

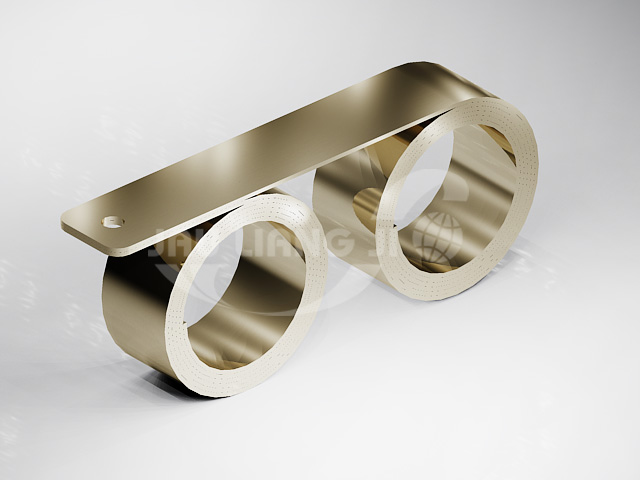

Common Installation Methods

Different installation methods are available for your product design. The following are some of the installation options for reference, or you can contact us by phone for specialist advice.

Examples of Installation

Inner diameter installation

Enclosure installation

Tandem connection

Single layer

Double layer

Back-to-back installation

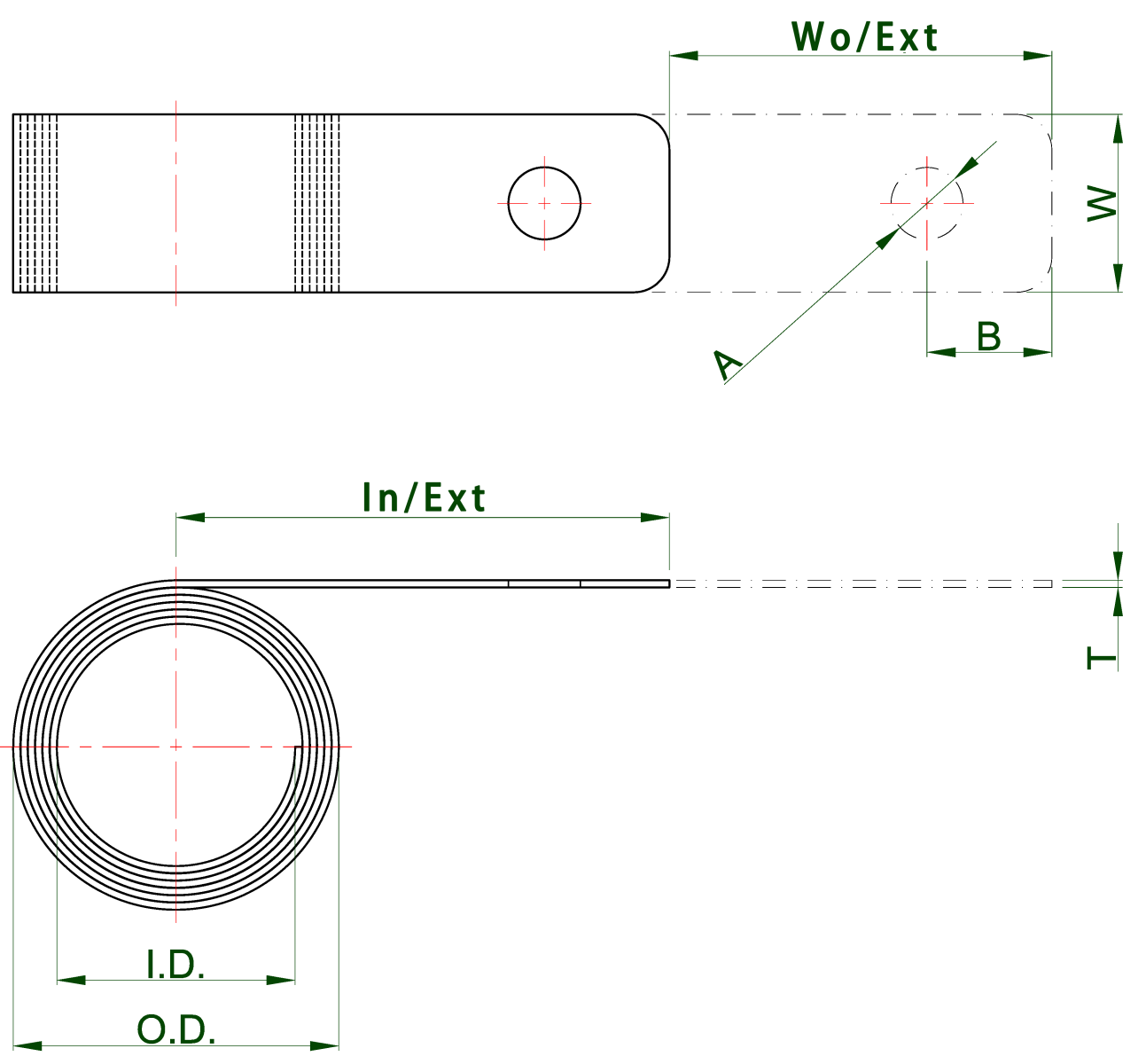

Dimensional Design

- Thickness of spring (T)

- Width of spring (W)

- Total length

- Inner diameter (I.D.)

- Outside diameter (O.D.)

- Initial extension (In/Ext)

- Working extension(Wo/Ext)

- Tail end design: (A)Pore size (B)Pore distance (R)R angle

- Load

- General tolerances: +/- 10%