Spiral Torsion Springs

Spiral Torsion Springs are also known as clock springs or flat spiral spring.

It is characterized by coiling the material into a spiral curve on a surface, securing one end of the spring without contact between the coils, while the other end is connected to a component of the rotating spring and rotates in a circular motion to produce a torque, whose angle of deformation is directly proportional to the torque. As a rule, spiral torsion springs are used for applications with a rotation angle of 360 degrees or less.

To satisfy the requirements of these different applications, Jau Liang Ji Co. offers customized spiral torsion springs for applications and solutions based on years of expertise and experience, with sizes to suit your needs. Our experienced engineers can assist you with your spring design, please contact us for more information.

Product Applications

Carbon brush holder for motors

Service life

Many factors affect cycle life including spring forming methods, edge condition and lubrication.

Different materials and storage methods may also affect the service life of the finished spring, such as frequent exposure to extreme temperatures or to corrosive gases.

Material

SUS stainless steel is generally recommended, but other special materials are available on request.

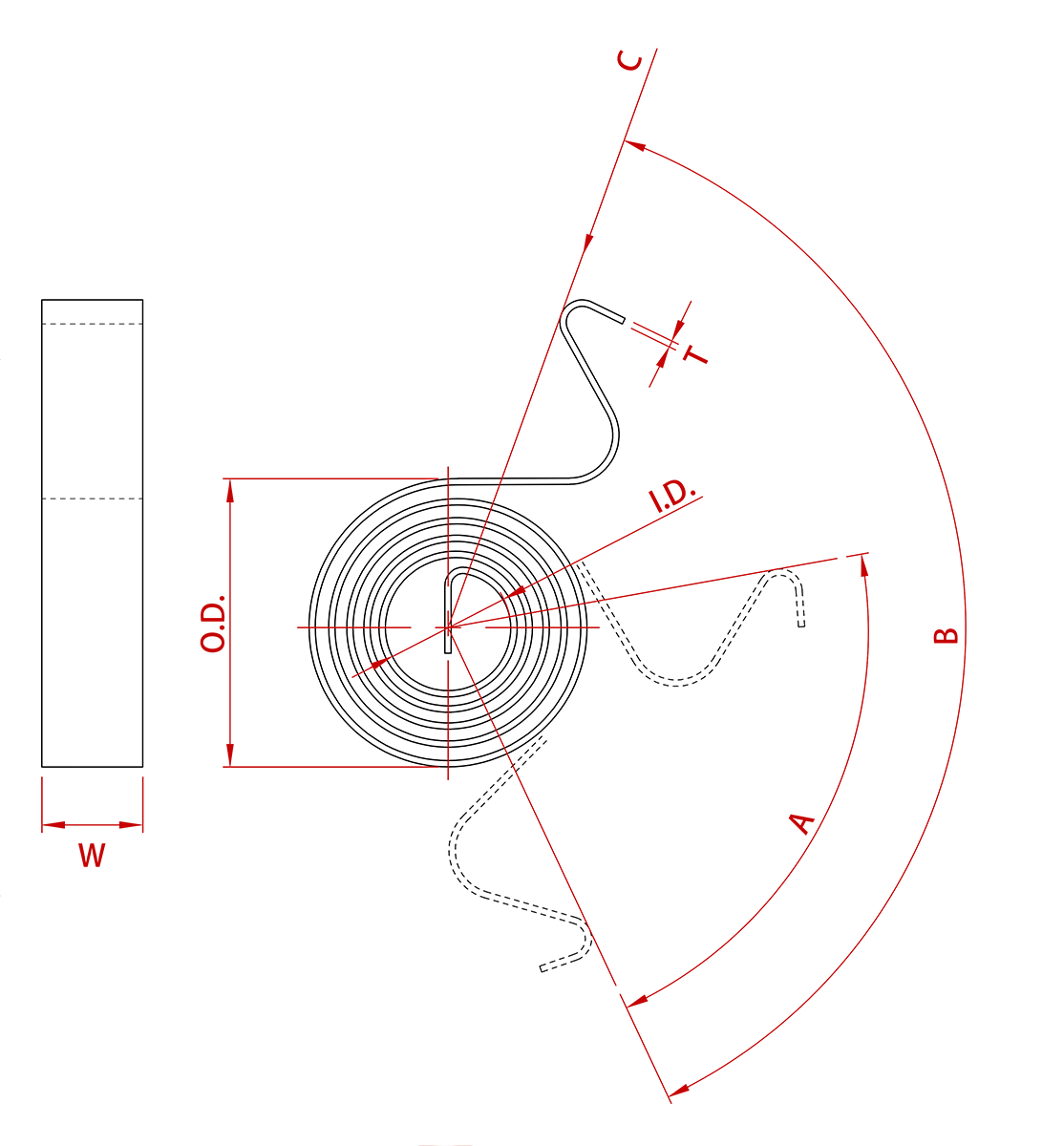

Dimensional Design

- Thickness of spring (T)

- Width of spring (W)

- Inner diameter (I.D.)

- Outside diameter (O.D.)

- Operating Range (A)

- Maximum working range (B)

- Free state position (C)

- Torque

- General tolerances: +/- 10%