Motor Brush Springs

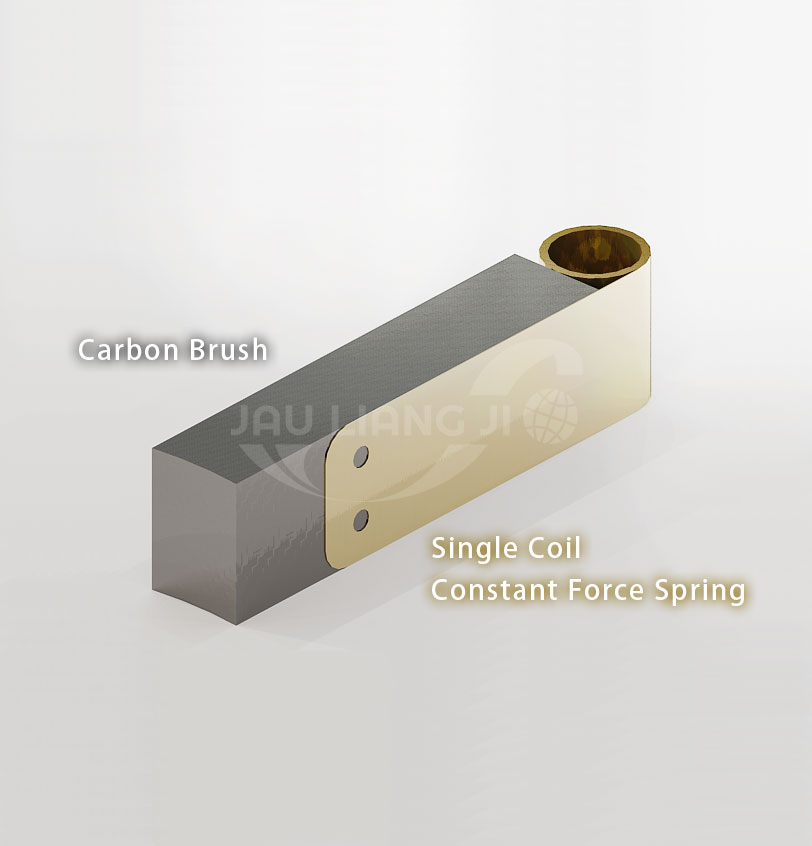

Available in both single and twin coil designs, the motor brush springs maintain the characteristics of constant force springs, which can reduce noise, sparks and electromagnetic interference when used in carbon brush motors, and keep the same pressure on the commutator regardless of the length of the brush.

To satisfy the requirements of these different applications, Jau Liang Ji Co. offers customized motor brush springs for applications and solutions based on years of expertise and experience, with sizes to suit your needs. Our experienced engineers can assist you with your spring design, please contact us for more information.

Features

Reduces carbon brush wear and increases brush life

Design miniaturization

Cost savings

Product Applications

Carbon brush motors

Service life

Many factors affect cycle life including spring forming methods, edge condition and lubrication.

Different materials and storage methods may also affect the service life of the finished spring, such as frequent exposure to extreme temperatures or to corrosive gases.

Material

SUS stainless steel is generally recommended, but other special materials are available on request.

Dimensional Design

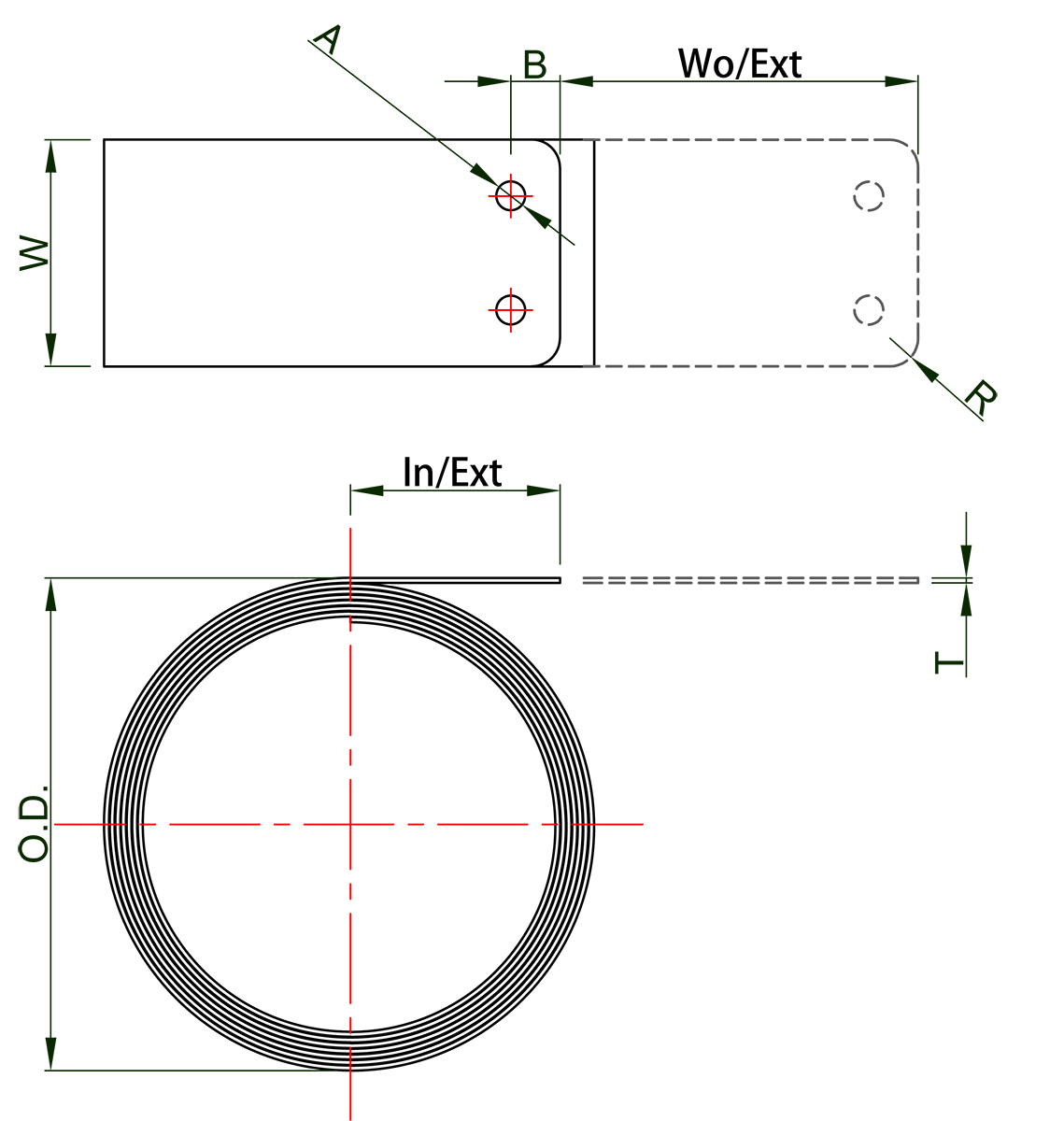

Type 1: Single Coil

- Thickness of spring (T)

- Width of spring (W)

- Outside diameter (O.D.)

- Initial extension (In/Ext)

- Working extension (Wo/Ext) > Length of carbon brush wear

- Tail end design: (A) Pore size (B) Pore distance (R) R angle

- Load

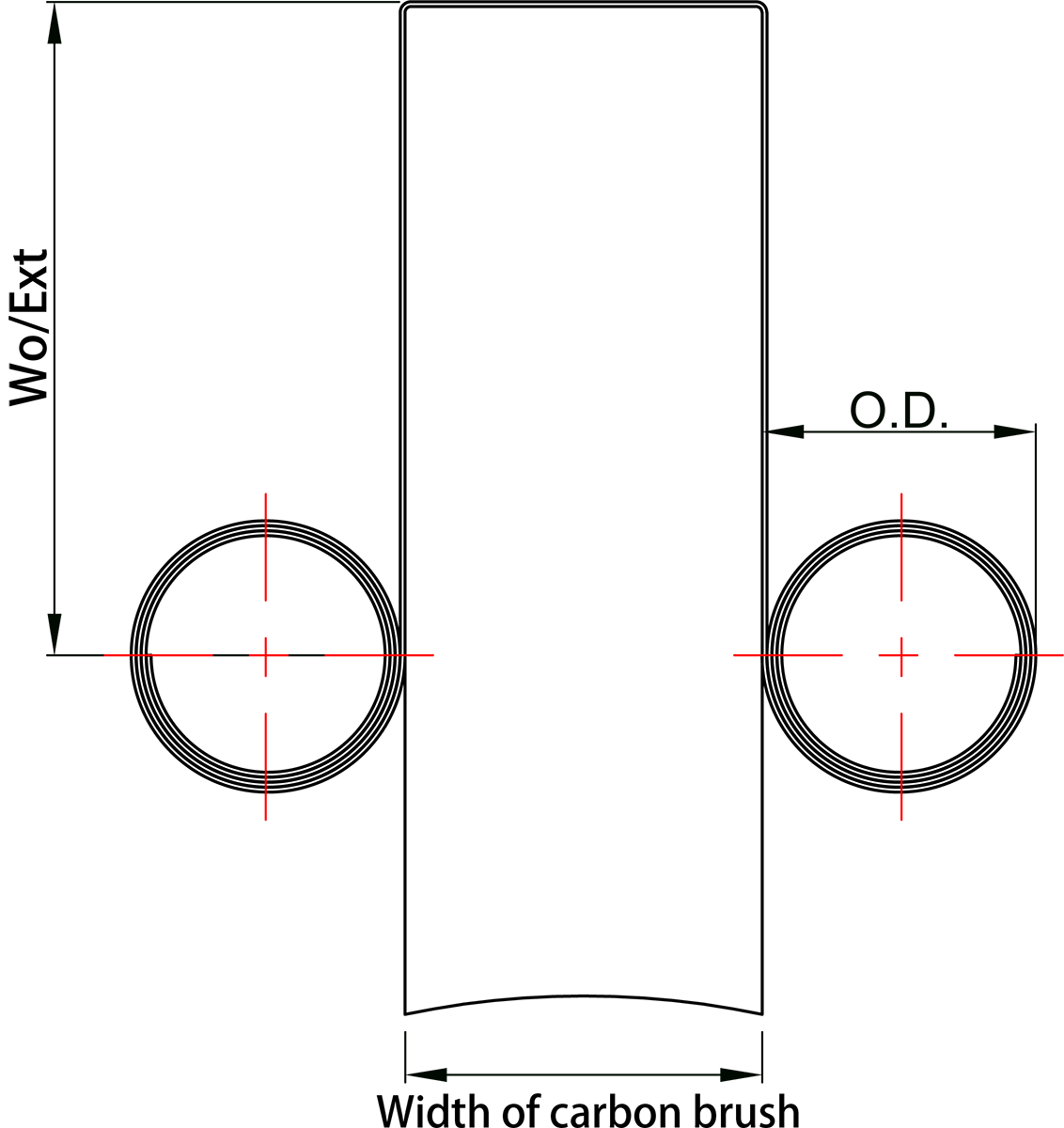

Type 2: Twin Coil

- Thickness of spring (T)

- Width of spring (W) > Height of carbon brush

- Outside diameter (O.D.): Outer diameter must be smaller than the space of carbon brush holdr

- Width of carbon brush

- Working extension (Wo/Ext) >Length of carbon brush wear

- Load